Are You Compliant with Title 22 (and the Daily Reporting Requirement)?

In 2015, a series of changes were made to the California Code of Regulations (CCR) Title 22 that impacted swimming pool operators. A few of the most significant changes included:

– Minimum 3.0 ppm free chlorine in all spas, wading pools and splash pads;

– Maximum pH of 7.8 (with range of 7.2 – 7.8);

– Incident response procedures were introduced for fecal, vomit, blood contamination and drownings.

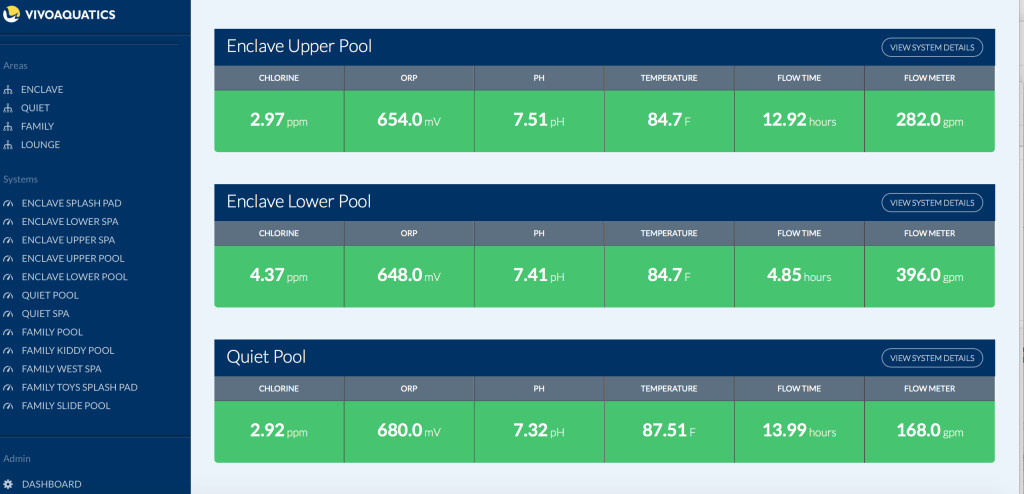

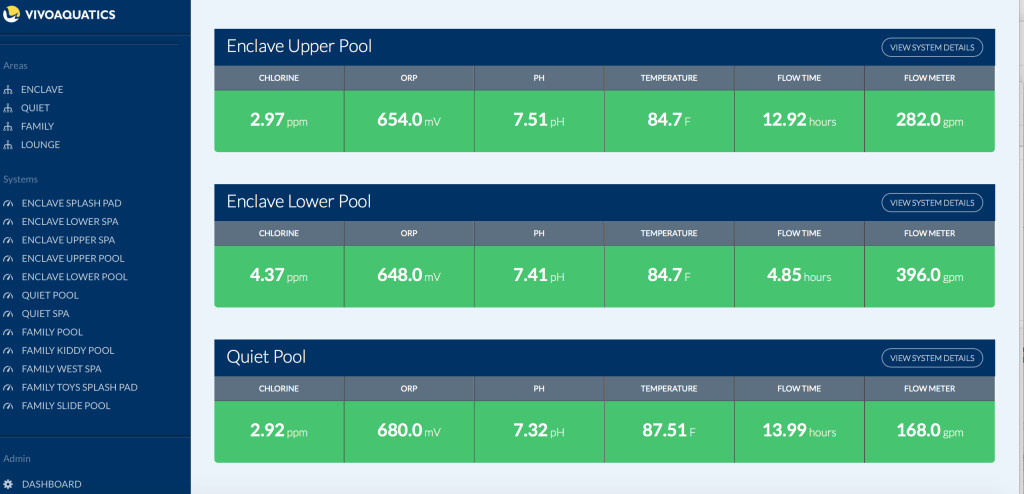

However, one of the more challenging changes was to Section 65523, Operation Records: “…the pool operator of every public pool open for use at a public pool site shall test the disinfectant residual and pH of the public pool water a minimum of once per day. The pool operator shall also test heated pools’ water temperature a minimum of once per day”.

While many local health departments provided pool operators with a grace period to implement such changes, we are now hearing from many clients that health departments are enforcing this daily reporting requirement as we head into 2016.

As a public pool owner / operator, there are three means of managing the daily reporting requirement:

1) Train on-site staff to test and record the water each day;

2) Hire an outside professional to visit the property each day to test and record the water;

3) Implement chemical automation and reporting.

While options (1) and (2) are certainly viable, they can be expensive and inconsistent. Employee turnover, the loss of testing equipment and overall unreliability are instead pushing many operators to chemical automation.

Chemical automation is not new. Most hotels, motels, fitness clubs and YMCA’s all rely on chemical automation. Title 24 requires all new pools being built be supplied with chemical automation systems. However, what is new is the ability to integrate reporting and remote monitoring with the chemical automation systems. Now, in addition to accurately feeding the pools and spa with the appropriate amount of chemicals, the monitoring and reporting will also track and report all readings to help properties comply with Title 22 and Title 24.

At VivoPools, we can help your property with all 3 options. And should you be interested in chemical automation and remote monitoring, we can offer you a lease system for as low as $199 per month that will improve the safety of your pool, mitigate risks and ensure you are in compliance with state law. Our automation and reporting have been implemented across a broad set of resorts,hotels, HOA’s, multi-family housing, fitness clubs, waterparks and many other facilities.

Please contact us today to better understand your options.

There are three main types of pool structures (Shotcrete / Gunite, Fiberglass, Vinyl Liner) with preferences often based upon region, economics, climate, length of swim season and even soil conditions.

A concrete pool is constructed by first building a rebar “cage,” in the desired shape. Gunite or Shotcrete, a high-tinsel concrete, is shot on at high velocity, then smoothed with trowels while still wet.

Tile and coping (stones on top of the structure) are applied. Decks are poured up to the shell. Then, the gunite is coated with either plaster or alternative such as an exposed pebble finish or other concrete blend.

A fiberglass pool is a pre-formed shell that is lowered into the ground. It is then backfilled and decks are poured around it. The pool may or may not have a ceramic tile waterline.

There are a finite number of shapes, colors and sizes. However, installation is about half the cost of a concrete pool and a much shorter construction time. They are also much easier and less expensive to take out if the homeowner no longer wants a pool in the backyard.

Fiberglass pools are relatively lightweight. Thus, once it is set into the ground and filled with water, draining can cause it to be dislodged from hydrostatic pressure (ground water under the shell). Be aware of high water tables and take great care in draining a fiberglass shell pools. Avoid long periods of time before refilling.

To build an in-ground vinyl liner pool, a hole is dug, walls made of fiberglass, metal, or concrete block are installed with a track on the top. The floor is covered with a special material to keep roots from breaking through. It is backfilled and a custom-made vinyl liner is hung from the track. After it is filled with water, holes are cut for return lines, skimmer(s), light(s), steps, etc. Vinyl liners stretch into place to pull out wrinkles. Once they are filled, they should not be drained until the liner is to be replaced – about every 8 to 10 years. Otherwise the liner can shrink and not have the elasticity to stretch back into place.

Vinyl liner pools are not structures. They are also susceptible to hydrostatic pressure. Liners can “float” up off the floor, but usually settle back down after the wet season. Pets should NEVER be allowed to swim in vinyl liner pools because their claws can inadvertently cut the liner. Other sharp objects can also tear or cut the liner necessitating a repair or replacement.

Fiberglass Overcoat: A process has been developed for existing swimming pools to have a fiberglass overcoat sprayed on and cured in the field. There are a few different methods, but essentially a mixture of resin and chopped fiberglass is shot on to the pool shell. It may or may not have a gel coat applied on top. It is then cured and filled with water. This material can be used on concrete pools, fiberglass shells and even to replace an in-ground vinyl liner.

Chemical Balance Based on Surface:

Plaster is a porous material and reacts with water, expelling alkaline materials, particularly in the first three years; pH will run high. Adding acid every visit to balance the high pH will affect the total alkalinity. New plaster is also more susceptible to staining than plaster that is over 5 years old. Thus, it is critical that water balance is within acceptable range the first few year of its life.

Fiberglass and Vinyl Liners do not react with the water. Thus the pH of each chemical, such as chorine and conditioner, will have more of an effect on the pH of the water than in a plaster pool. It is best to not use Trichlor in these pools.

Fiberglass pools should be maintained at at the higher end of the saturation index range than plaster pools to prevent a condition called cobalting, which is dark staining or streaking on the surface. If cobalting does occur, it can be treated with ascorbic (citric) acid.

Further questions about pool structure? Contact us today to get your questions answered!

We have previously discussed the three keys to safe and clean water. Chemical balance is perhaps the most important element to maintaining water for both residential and commercial swimming pool accounts. Poor water chemistry can not only cause staining and damage to the pool’s surface and equipment but can also cause swimmer discomfort and illness. Proper water chemistry should be checked for and maintained each week. Unbalanced chemistry can allow for algae growth and algae harbors and protects germs and bacteria, allowing it to thrive and putting your swimmers health at risk.

There are 5 main aspects of water chemistry to keep balances and to check for regularly. These 5 aspects are:

- Free and Available Chlorine (FAC) – maintained at 3 to 5 ppm (parts per million)

- pH Balance (Power of Hydrogen) – maintained at 7.4 to 7.6

- Total Alkalinity (T.A.) – maintained at 80 to 120 ppm (parts per million)

- Conditioner (Cyanuric Acid) – also called stabilizer, maintained at 30 to 50 ppm (parts per million)

- Calcium Hardness – maintained at 180 to 500 ppm (parts per million)

There are a few other conditions that can also be checked, depending on your equipment and factors around your pool:

- Salt, Salinity (Sodium Chloride) – Salt is used with Salt generated chlorination systems only and should be maintained at 3250 to 3500 ppm (parts per million) though different manufacturers will have some variance in their recommended salinity levels (with some up to 4000 ppm)

- Total Dissolved Solids (TDS) – a measurement of all solids dissolved in a sample of water and a general indication of the waters age. Proper TDS levels and recommendations will be given on a TDS test kit.

- Phosphates – a measurement of microscopic dead plant material and food for algae. Measurements for recommended phosphate levels will be given on any phosphate test

Contact VivoPools today to help check your pool’s chemical balance!

We are often asked, what are the keys to maintaining clear, clean and healthy swimming spa and pool water. The primary requirements, whether it be for a residential or commercial swimming pool are Circulation, Filtration, and Chemical Balance. Whenever your water becomes cloudy, unhealthy or algae begin to grow it can be due to a breakdown in one or more of these three key conditions.

Circulation:

Circulation is the flow or current in the water. It is important to have turn over your water 1 time per day, which typically means your residential pump will run 6 to 8 hours per day for a pool, or 1 to 2 hours per day for a spa. Pool pumps within a public pool will typically operate 20-24 hours a day. Water circulation is important to keep the chemicals in the water evenly mixed, regulate the overall temperature of the water and make it more difficult for algae to settle and take root. When a body of water is not circulating it becomes stagnant. Circulation also helps get any sanitized and oxidized material in the water to the filter to be collected, keeping the water clear.

Filtration:

Filtration occurs when water is pushed through the pool’s filter. The filter collects any dirt and debris that the pump pushes into it or is vacuumed up, sending the clear and filtered water back into the pool. There are three standard types of filters that you will come across in swimming pool and spa service. These three filters are Diatomaceous Earth filters which have a series of grids inside them that hold a fine powder filter media, Cartridge filters which have a large cartridge or a variety of smaller cartridges inside which collect the dirt and debris and Sand filters which are filled with a fine sand in a sectioned compartment and force the water through the sand with the sand collecting the dirt and debris. All of these types of filters should be cleaned and maintained regularly.

Chemical Balance:

Chemical balance is the most important key to maintaining clean, clear and healthy water. Bad water chemistry can not only cause staining and damage to the pool’s surface and equipment but can also cause swimmer discomfort and illness. Proper water chemistry must be checked for and maintained each week. Unbalanced chemistry can allow for algae growth and algae harbors and protects germs and bacteria, allowing it to thrive and putting your swimmers health at risk.

Get your pool in check today! Contact VivoPools and we would be happy to get you your safe and clean pool water!